3D Printing

Fxmodels has added a 3D Printer to our list of capabilities. This in-house system allows parts designed on the computer in 3D to be ‘printed’ out in a final, finished physical 3D form. Often confused wtih SLA, which is usually a lesser resolution process, this method of part building on the machine is analogous in principle to how an MRI or CT Scan works. With an MRI or CT Scan, the part of body being scanned is scanned in successive 2D layers from the bottom up for example. If you take enough layer images and stack them all together, you can build a 3D computer model of the part of the body being scanned. With 3D printing, you build the 3D Computer model FIRST, and then slice it up into layers, from a coarse resolution of 5 thousandths per layer, to a very fine resolution of 0.5 thousandths per layer.

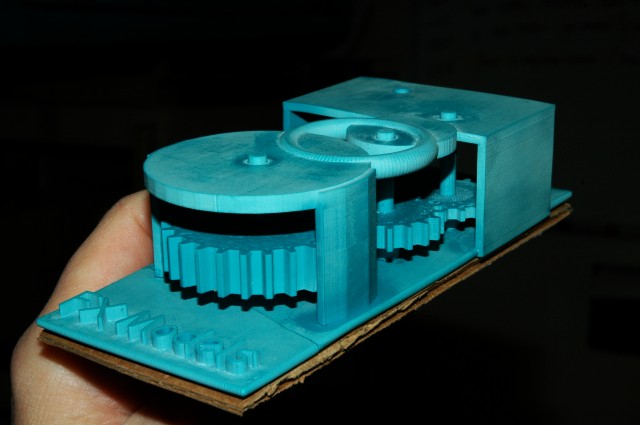

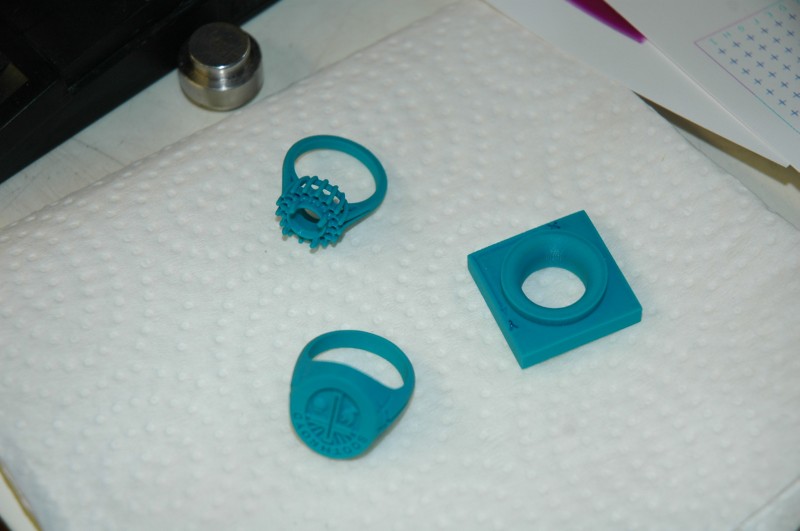

Fxmodels has the capability to “grow” parts in this way in a volume of 6x6x12″ in size. Parts larger than 12″ long would be broken up in the computer model and printed successively on the machine and be assembled afterwards. Regardless of how they are grown, they can be molded after coming off of the machine, and reproduced effortlessly in multiples.

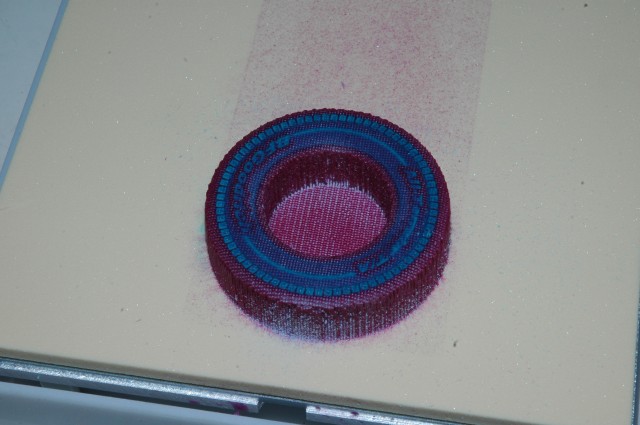

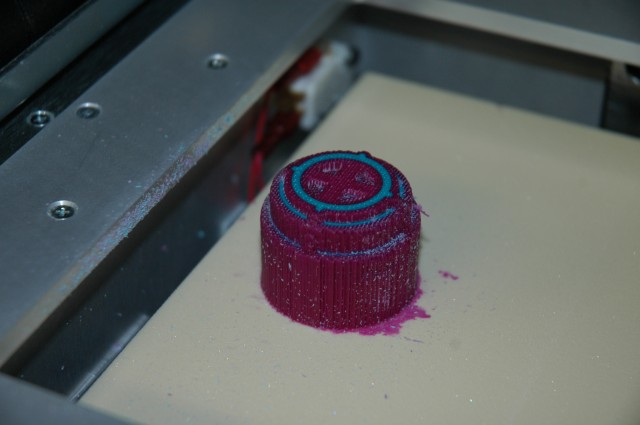

The material that the machine produces is not a plaster or corn starch type material, but a true Thermoplastic. During the grow process this blue plastic is laid down by one of two ‘print heads’ and then encased in a layer of support material . The reason for a support material is that if a highly delicate part is grown, the wax ‘supports’ the delicate part during the build so it doesnt sag. After all, as the plastic is laid down, it is molten and needs to cool. Once the part is done, it looks like a purple mass with something inside. The something inside is the blue plastic part and the purple mass is the wax that will be dissolved away with a heated bath of a solvent. The final result is a plastic part.

Builds can take a long time. The parts shown on this page were 11 hours to build, and all were built at the same time. The process takes a long time but considering how long it would take to build the pieces manually, the savings is immediate and obvious. In the case of these particular test pieces though, they are simple relative to the benefit received by making these as computer models first and then growing them. But for complicated models, the process is worth its weight in gold for turnaround and ease of manufacture.

See this page for updates and watch the process unfold.